首页»

科学研究

首页»

科学研究

陈晓老师—Chemical Engineering Journal (IF: 16.7)

2020-05-05

网站编辑

碳纳米管基柔性复合相变材料

Abstract: Currently, most reported composite phase change materials (PCMs) are powdery shape, which require secondary processing for practical applications. Although some monolithic composite PCMs have been developed, their flexibility usually undergoes a remarkable reduction or even complete disappearance when supporting materials are infiltrated with PCMs. To solve this problem, we fabricated a flexible supporting material with a folded layer bridge network structure by dispersing carbon nanotubes (CNTs) in acetic acid solution of chitosan (CS) with poly(vinyl alcohol) (PVA) using a directional freezing method. Then CS/PVA/CNTs (CPC) scaffold was infiltrated with polyethylene glycol (PEG) to prepare PEG@CPC composite PCM. The resulting flexible composite PCM displays excellent mechanical properties, such as high tensile strength of 2.42 MPa and bending resistance of > 100 cycles. Moreover, it displays outstanding thermal properties, such as high crystallinity of close to 100% and encapsulation ratio of 92.6 wt%. This work provides a simple method for preparation of flexible monolithic composite PCMs for many potential applications, such as wearable fitting-skin temperature-controlled materials.

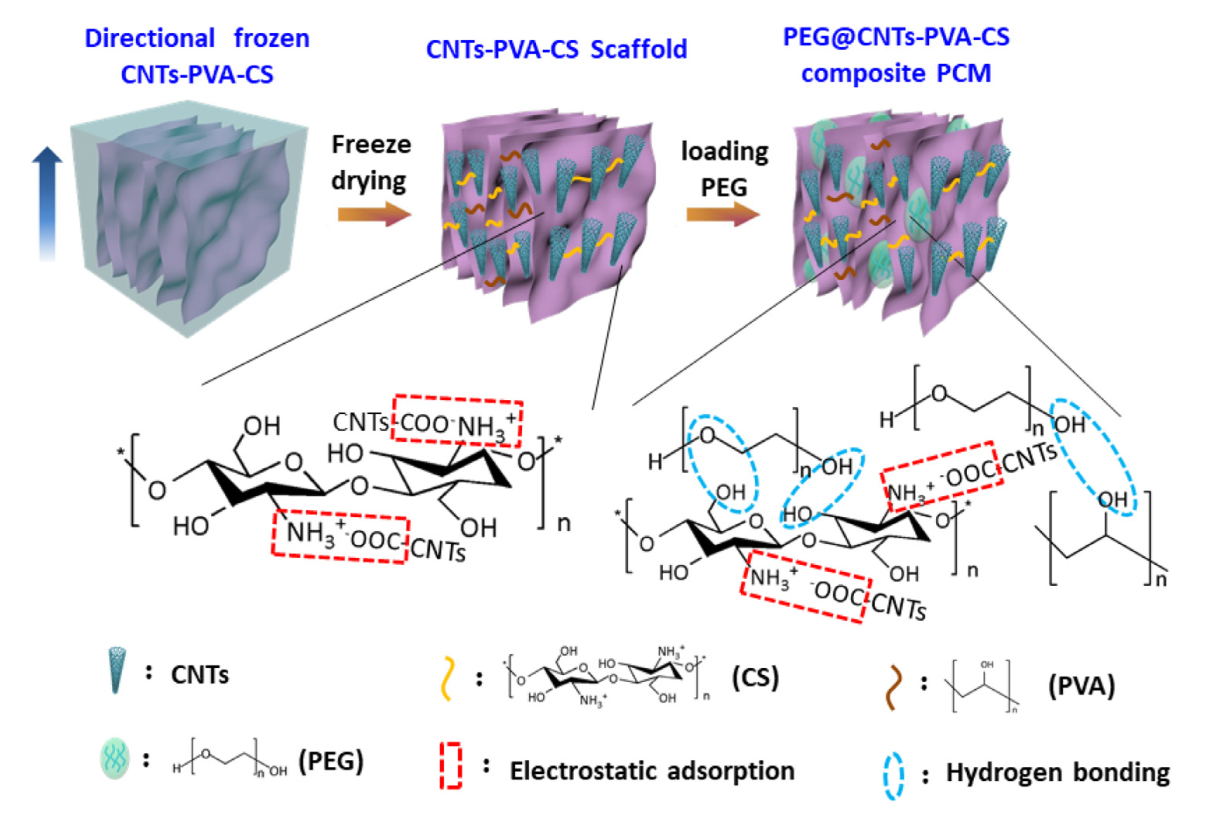

Figure 1. The fabrication process of CPC and PEG@CPC composite PCM.

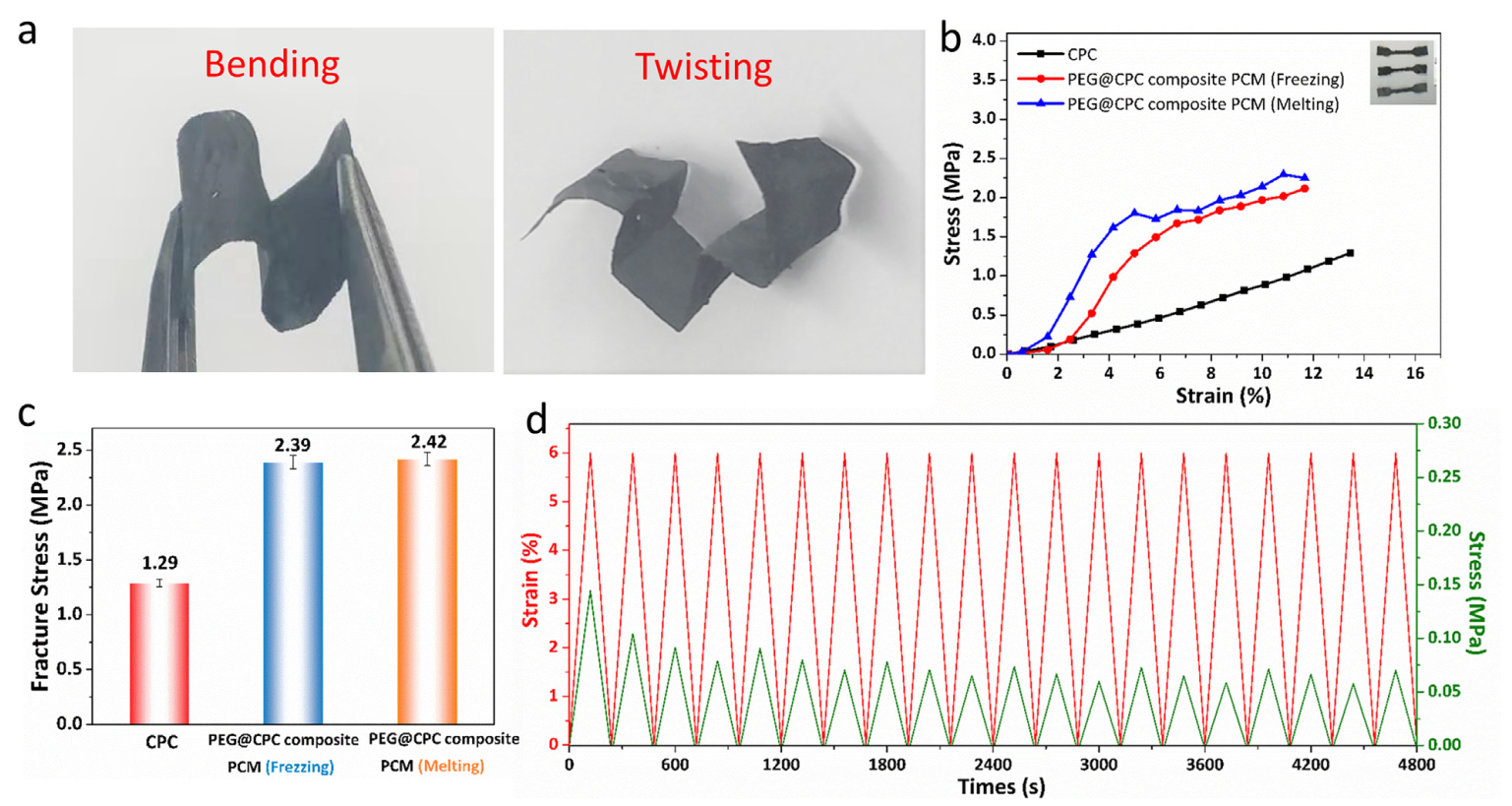

Figure 2. a) Digital photographs of monolithic composite PCM regarding folding show. b) Typical tensile stress–strain curves and c) Fracture stress histograms of CPC scaffold, PEG@CPC composite PCM in the freezing and melting states. d) Representative tensile stress–strain curves of the flexible composite PCM during 20 times loading–unloading cycles.

文献链接:Piao Cheng1, Hongyi Gao1, Xiao Chen*, Yuanyuan Chen, Mengyi Han, Liwen Xing, Panpan Liu, Ge Wang*. Flexible monolithic phase change material based on carbon nanotubes/chitosan/poly(vinyl alcohol). Chemical Engineering Journal, 2020, 397, 125330.